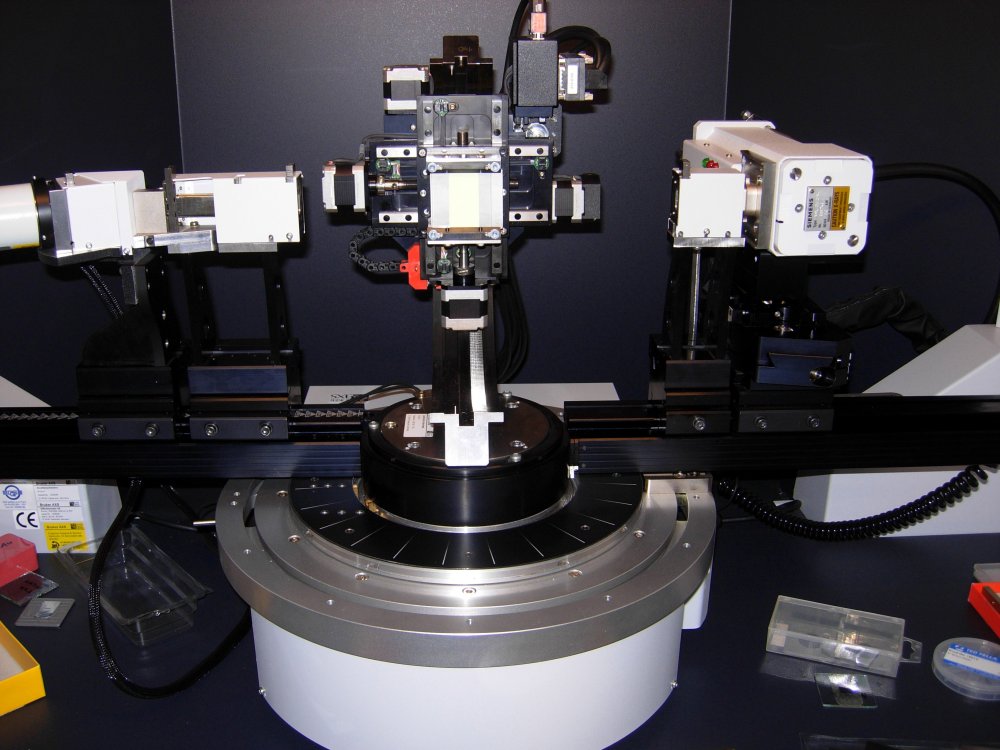

XRD Bruker D8 Advance.

Centric Eulerian cradle with sample holder, anode and NaI scintillation detetector.

Technical data

X-Ray Source

2.2 kW Cu long fine focus ceramic X-ray tube

1.8 kW Co long fine focus ceramic X-ray tube

The running conditions for the X-Ray tube are 40 kV and 40 mA, the power supply controls these with a stability of better than 0.01% for the high voltage and 10% of the variation of the supply for the current.

Goniometer

Geometry: Brag-Brentano (theta/2theta, theta/theta)

Neasuring circle diameters: 435, 500, 600 mm

Operating position: Horizontal

2theta circle: -4º to 170º

Reproducibility +/- 0.0001º

Centric Eulerian Cradle

Chi circle: -11 to +98

o

Phi circle: unlimited

X translation: +/- 40 mm

Y translation: +/- 40 mm

Z translation: 2 mm

Sample load: 1 kg

Sample height: 40 mm

Detector

The detector is a NaI dynamic scintillation detector with a maximum count rate of 2 x 10

6 s

-1 (although it should not be exposed to in excess of 5 x 10

5 s

-1 for periods longer than about 1 second). A computer controlled absorber is mounted directly in front of the detector and is used to attenuate the beam by about 2 orders of magnitude. To change the angular resolution several slits (0.05 to 2 mm) are available to be placed in front of the detector, as are a set of Soller slits to allow for small samples. Attenuators made of Cu, Fe and Ni are also available and can be manually placed in the beam, by inserting them into the slit holders in front of the detector. The detector electronics are capable of a count rate up to 3 x 10

7 s

-1.

Secondary Graphite Monochromator

Coling System

Cooling water minimum flow rate: 3.6 l/min

Pressure of cooling water: 4 to 7 bar

Chiller: ATC KT1 (1 kW) and Danfoss heat exchanger (4.5 kW) (home made solution)

Software

The software suit is all windows based, and enables the user to both acquire and analyse data.

Automated data acquisition

Analytical Capabilities

Phase identification - Qualitative with Search-Match programs

Quantitative analysis - Rietveld method

Residual stress

Texture analysis (Pole figures and orientation distribution function)

Retained austenite analysis

Carbide phase analysis in steels