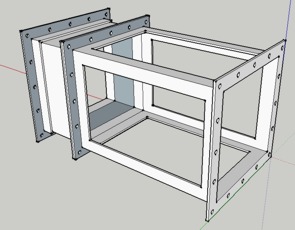

The main part of the wind tunnel is measuring chamber. This is the space in which we will implant test models, is made from steel brackets. The plan of the structure is draw Denis Percic from G1B.

When we made frame chamber, they helped us some of our students of technical and vocational schools. The work was done under the expert guidance of teacher Janez Gradic.

Primoz and Omer from S1C for manual work.

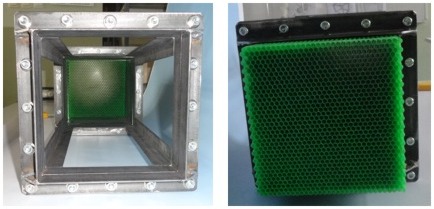

Chamber with screwed flanges and segments for air spoiler deflector. Individual segments of the wind tunnel can exchange between themselves joined together by screw connections. This possibility allow us to testing the device itself and any changes.

The chamber was finished on 17 April, 2014. The next day Clemen and Leonard incorporated into the system wind tunnel.

Matic and Klemen were dimming (to be coloring) background chamber that no major disruption light reflection. After that they exact fitted of the sides. Any damage to the paint would require re-work.