Iskra Feriti and their components

Foreword

|

|

|

Managing

director Marko Zivec:

We have assumed

the commitment to run the business in conformance with the ISO9001

Standard series and its requirements. In May 1995, we were awarded

the Certificate of Conformance with ISO9001 by the German auditor

DQS. This decision was made because of our major export market. |

by Leopold

Knez

by Leopold

Knez

1. Foreword

The Iskra Feriti (Iskra Ferrites)

company has more than 40 years’ experience in the production

of ferrite materials and products. The production programme was

established in 1954 within the framework of the Electronics Research

Institute in Ljubljana. The production of ferrite materials and

products was begun in 1957. We have produced ferrites at our present

location at Stegne 29 since 1966. In 1973, we founded a subsidiary

for wound component production in Ljubno ob Savinji.

The development of both programmes takes place in Ljubljana. Our

company co-operates closely with the Ceramics Division of the

Jozef Stefan Institute and with the Faculty of Electrotechnik

in Ljubljana. This co-operation has enabled the development of

our own knowledge, and freedom from licensing agreements. We have

acquired patents for new products and technical solutions in both

fields.

|

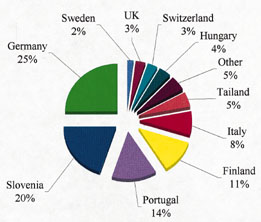

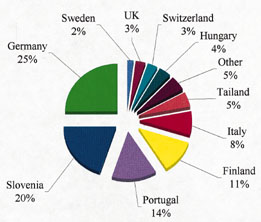

Fig. 1: Our major

markets in year 1997 |

In order to keep track of costs

more easily, the production of ferrite materials and products

and wound components was split between two programme centres,

PC Feriti and PC Navite komponente. We have 316 employees in Ljubljana

and 126 in Ljubno. Soft and hard ferrites and products, as well

as a part of the production of wound components are produced in

Ljubljana. In Ljubno, we produce only wound components.

Over 85 % of our products are exported to European markets. Our

goal is to use our own ferrites as much as possible in wound components,

and to market them in that form. We consider flexibility to be

our comparative advantage. We can produce ferrite cores for wound

components in a relatively short period of time.

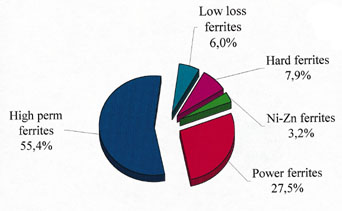

There are around 60 producers of ferrite materials world-wide,

producing a total of around 200,000 tonnes of ferrites. We produce

around 700 tonnes, of which 600 tonnes are weak ferrites and 100

tonnes strong ferrites. Our 1997 turnover for the two programmes

together amounted to DM 30 million.

|

|

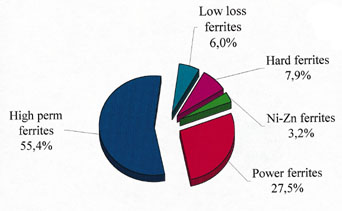

Fig. 2: Iskra

ferrite survey. |

2. Programmes

2.1. Soft ferrites

We produce a wide range of

soft ferrite materials, from low loss, high permeability to power

ferrites and cores. We produce standard and cus-tom designed ferrite

cores from these materials such as: ferrite rods, tubes, E and

U cores, RM and FL cores. We also produce tool kits and coil spools

for professional, industrial and general consumption. We are well

acquainted with the technology of pressing and powder injection

moulding of ferrite cores.

|

|

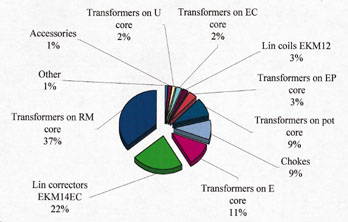

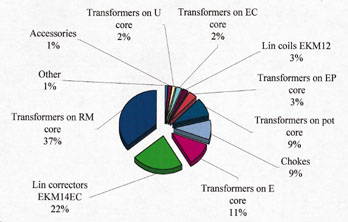

Fig. 3: Iskra

wound components survey |

2.2. Hard ferrites

We produce polarised and non-polarised

oxide magnets in various shapes and dimensions for the automobile

industry, household appliances and other consumer application.

|

Fig. 5: 16-tower

box kiln for sintering ferrite cores. |

2.3. Wound components

The structure of individual

products by percentage of total company sales is given in figure

3.

Transformers on RM cores for subscriber telephone exchanges make

up the major share of wound products. We have developed coil formers

and assembly technology to precise detail. We have an automated

line which assembles and controls all prescribed parameters. Results

of measurements are processed continuously. The quality of the

products is one hundred per cent controlled.

Recently, a new method has emerged of producing transformers with

a more enclosed core. The influence of magnetic fields from the

environment and on the environment is further reduced in these

products.

The programme of non-linearity correctors is very important. We

rank among the most important producers of this type of component.

This is especially true for computer monitored automated workplaces.

The correctors have specially designed soft ferrite cores with

two separate coils. The main coil changes impedance in relation

to the strength of the deflected current. The control coil can

be set to different values in various picture resolutions. The

permanent magnet presets the correct working point.

|

Fig. 4: Computer

controlled measurement system for ISDN Transformers. |

3. Innovations

3.1. Planar transformers

We are preparing a new planar

cores for the telecommunications field which will be installed

directly onto printed circuits board, where it will already be

a part of the coil. This type of transformer will be used to feed

individual electronic complexes. Central supply to telephone exchanges

will be divided among individual complexes. Voltage will be reduced

to 5V, 3V or even 1.8V. Dissipation into integrated circuits will

be decreased at these voltages, there will be less interference

and product lifetime will be extended.

3.2. New transformers for

ISDN telephone-exchange

For special applications such

as RM transformers, we are designing new types of transformers

with cylindrical and bar-shaped cores. Their advantage will lie

in lower dissipation of magnetic fields into the environment.

Figure 4 shows the computer controlled measurement system for

ISDN transformers in our production. This system can measure all

prescribed electromagnetic parameters for ISDN transformers.

3.3. Filters for telecommunications

Every subscriber line is connected

to the telephone exchange with an electric filter. SMD p-filters

are composed of capacitors and a toroid core with a double electrically-compensating

coil. The small 4 mm toroid cores will be machine wound in order

to produce an appropriate p-filter and inserted into a plastic

housing with four SMD contacts. On this basis, we will develop

our range of components for special applications.

|

Fig. 6: Manipulaor |

3.4. Non-linearity correctors

We will exchange the classical

ferrite magnets in standard non-linearity correctors with powder

injected magnets. The new construction will allow us to lower

production costs and to compete on the consumer products market.

3.5. New ferrite materials

In the field of power applications,

we have developed the low-loss power Mn-Zn material 35G, which

has an initial permeability of 2200. In the future, we will additionally

decrease power loss by increasing permeability. In the field of

ISDN transformers, we have developed a high-permeability Mn-Zn

material called 32G with an initial permeability of 12,000. Materials

are being developed with an initial permeability of 15,000. We

have achieved top quality of ferrite cores by a very sophisticated

box kiln for sintering, Fig.5.

3.6. Multilayer chip chokes

Multilayer chip chokes are

gradually replacing classical chokes. They will be used first

in telecommunications and will later be applied to other fields

in electronics. We have developed a low-temperature Ni-Zn material

for multilayer chip chokes which is sintered at a temperature

of around 900oC. We are developing further technological processes

for the production of these chokes which will cover a wide spectrum

of inductivity and frequency ranges.

by Leopold

Knez

by Leopold

Knez