GUIDELINES

THAT I PICK UP FOR DESIGNING THE FOOT LAUNCHABLE MICROLIGHT

SAILPLANE

PERFORMANCE

GOALS:

- To achieve similar or better performance than

modern flex wings hang gliders (topless – competition type) L/D around 15 to

20 and sink rate smaller than1m/s

- Ability to safe take off and landing on ordinary

foot launch sites in our country

- And most of all, having fun building it and flying

it !!!

HANDLING

GOALS:

- Easy assembly /deassembly and transport on top of

car (using apropriate modified rack)

- Easy manouvering during entering the cockpit and

attaching the pilot harness.

- Easy moving with glider to the launch place even in

wind (lightweight and small enough !)

- No need to take care of the angle of attack during

early phase of take off (acceleration phase)

- Light controls and electrically (threaded rod)

driven flaps

- Controls for yaw with left hand (at side of

cockpit) and both legs (in nosecone), depend of the pilot position (standing

or sitting)

- Controlls for pitch and bank for right hand at side

of cockpit

SAFETY

GOALS:

- Protection of the pilot in case of crash during

take off or at landing if the vehicle speed somehow exceed the runing ability

of the pilot, what can occure in windy condition and if rotors are passing the

starting/landing place, and somethimes when pilot make some nonsens

mistake..

- Low stalling speed at start/land

configuration

- Gentle stall behavior in zero flap

position

- Lightweight construction

- Sailplane must be equipped with balistic recovery

parachute, aiming rearward

WHY DESIGNING (BUILDING

AND FLYING) FOOT LAUNCHABLE SAILPLANE WITH SUCH POOR

PERFORMANCE?

Well I am hang glider pilot

since 1979 and even flying the sailplane for around 45 hrs solo, I am stil

emotionally attached to foot launch comunity and hang

gliders.

I think it will be fun to

show up on a hill with such design and having fun simply soaring on ridge

updraft or nearby thermals, beside hang gliders and paragliders, but having 3

axes aerodynamic controll over glider…

The main purpose of this

glider would be to made some futuristic design with no similiraty with present

foot launchable sailplanes as:ULF-1, Carbon Dragon, Super Floater, Swift and

other different types of tailless rigid wings.

The design should be of

simple construction adapted for the homebuilders. There is not an attempt to

commercially use of this design.

DESIGN

DESCRIPTION

WING

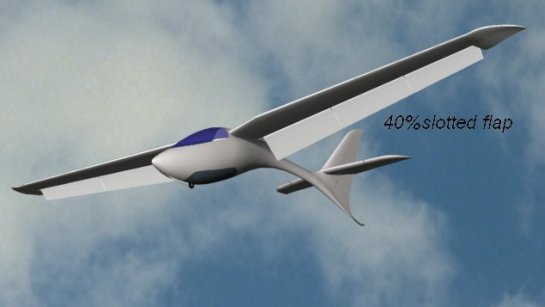

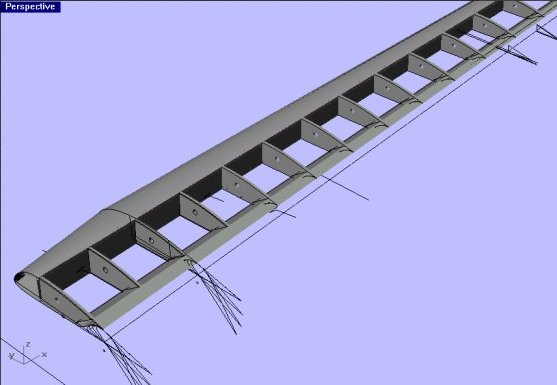

Simplified view of wing...

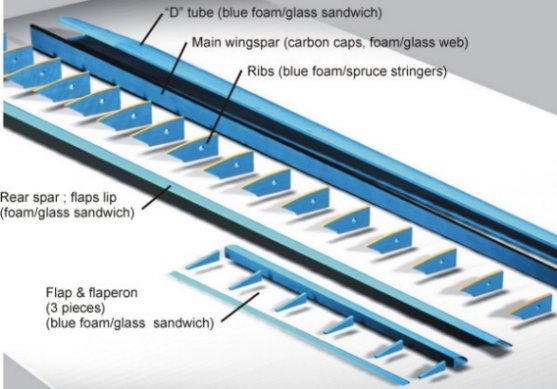

Main wing components (exploded view)

To achieve safety, handling

and performance goals I decided so:

- The max wingspan should not exceed 11m (for ground

handling reasons)

- The wing will have full span slotted flaps with

short lip and close to 40% of chord (for lift coefficient about

2,8)

- Flaps will be spanvise separated in three pieces

(wing flexibility at flaps deployed reason). The outer piece will operate as

flaperon.

- Down motion of aileron, wil be reduced to zero at

full flaps to avoid unwilling stalling of wing tip

- The wing will have two spars, one at end of torsion

nose and other near flap slot. Spar caps will be of prefabricated ready to use

commercially available graphite rods

- Torsion nose will be of sandwich construction with

incorporated front spar, but part between two spars will be made with ribs and

covered with lightweight fabric.

- Rear part of wing (flaps slot) will be of moldless

foam and composite construction incorporated with rear

spar.

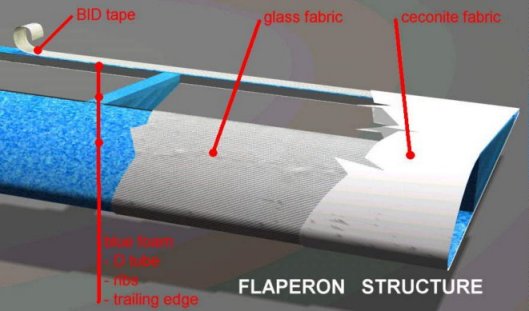

- Flaps nose will be of foam and composite moldless

construction, making stiff torsion box, the rest of flaperon will be with ribs

and covered with lightweight fabric.

- During flight, the flaps will be driven via

electromotor driven threaded rood, controlled with simple buttons in cockpit

(preffered on one of control sticks) The motor unit will be small model

aircraft motor with apropriate reduction gear and small yet powerful NI-Cad

battery pack. On starting place will be also a possibility to manually prepare

the flaps in down position.

- The wing will be of cantilever design (or maybe

with short wing strut, to solve complexity and stress at wing fuselage

joint).

- The wingtips wil be short sabre alike, but they can

be deassembled and replaced with any type of tip including small

winglets.

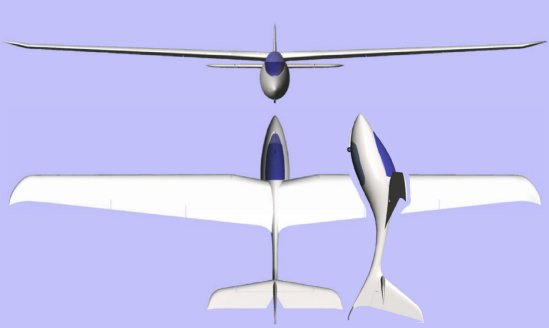

TAIL SURFACES

HORIZONTAL TAIL

- Horizontal tail is almost conventional with

stabilisator and elevator.

- Stabilisator is relatively small and is made as

foam/composite moldless construction.

- The elevator is structural similar to flaps and is

partly aerodynamical and mass balanced.

- The horizontal tail is deatachable and is mounted

in the fin slot and secured with one pin.

VERTICAL TAIL

- The fin is structural part of rear fuselage and is

of foam/composite moldless construction.

- The rudder is is structural similar to elevator and

is partly aerodynamically balanced.

FUSELAGE

- Fuselage is made of 3 small main parts that are

later structurally assembled.

They are as follows:

1. cockpit area with nose cone and two cockpit

sidewalls

2. central part with two main bulkheads and wing

attachment points

3. tail cone with rudder fin

- The fuselage is build as foam/composite moldless

construction

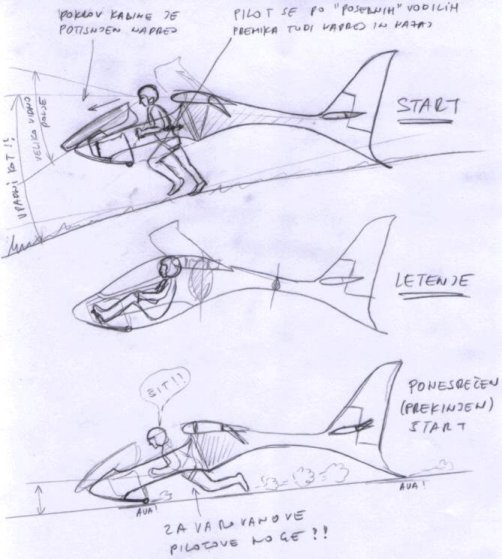

- Canopy is made of thin free blown plexi and is

mounted on the wide composite frame, which can be sliding forward for entering

in the cockpit.

- Bottom part of the cockpit area is open for the

pilots legs. For the running down the slope there is enough space available

not to disturb normal running.

- The openning at the bottomius closable in flight,

and this is achieved by fabric cover with some stringers for stiffening and

better contour.

- Pilot is atached to the glider with harnes similar

to the early paragliders and is hanging from main fuselage bulkhead. Pilot

also wear shoulder straps for rising the glider on the ground until the lift

pull the sailplane up.

- Flihgt controlls ate of two short controll sticks

placed in left and right close to the sidewall of cockpit

area.

- The balistic recovery system is placed between

fuselage bulkheads and is aiming rear and up toward the fin.

- The strange or futuristic shape of fuselage is not

only atractive but also allow to pilot great visibility during start and

flight, and most of all protect the pilot (his legs and back) in case of crash

at start or landing.

- In front, just behind the nosecone, the sailplane

is equipped with short skid and small wheel, and at rear below the tail there

is a short skid too. With this parts the glider can be pushed around without

need to rise it from the ground at all.

- The tail skid also support tail of the sailplane

during take of and preventing the wing to achieve to big angle of attack.

- The landing will be done simply by belly landing

(on the skids and wheel) with pilot in sitting position.

-WHY ARE THE FLAPS DIVIDED

IN 3 PIECES?

Because the wing will

defenetly be bend up during flight, the invisible »hinge line« of flaps wil be

distort from ideal straight line to some kind of arc. If flaps were hinged say 3

times per halfspan, it will be hard to rotate flaps (midle hinge not in line

with outer ones), and flaps will be stressed much more, because it should be

bend at unpleasant direction. At flap retracted it will bend at same manner as

main wing, but at deployed flap it looks that trailing edge of the flap will be

stressed in tension, and will probably break. This hinge missaligment would

probably cause some extra friction in hinges thus rising the command forces to

operate flap…Carbon Dragoon fight this with differential drive 1:4 (+4/-16 if I

remember right)

If we take a piece of paper,

and bend it at long edge (performing simplified shape of wing with deployed

flap) we soon discover that if trying to bend the wing, the bended part- flap,

will take almost all bending load. I dont want to flap take any necessary load

in my design.

So, if I divide flap into 3

parts per halfspan and hinging each part only twice (with ball bearings) I avoid

almost all unwilling stresses of the flap, regarding any wing bending (in

aeroelastic range of operation). Well, the gaps between flaps panels will

decrease their effectivines to some degree, but the gap can be filled with some

kind of foamy material, to avoid air leaking..

-WHY ONLY OUTER PART OF FLAP

ACT AS FLAPERON?

The simpliest way (for

calculations and aso for manufacturing reasons) is to use so called flaperons on

wing for both function (high lift device + controll over bank angle) as is done

at Carbon Dragon.

But I prefferd to divide

them into 3 parts and to use inboard two sections to act as flaps and outer one

as flaperon. Why?

If we imagine ourself just

prepared on the hill for launching, we want to have all benefits

of our high lift device. So, any change of flap(eron) setting toward up, wil

cause less lift. But we want all lift we can get from the wing at such low

speeds during starting phase. If we must rise or lower the tip of wing (if

sudden gust on start put the wing out of level attitude) we must produce a roll

moment over centerline of sailplane. This is simply done by changing the lift

force on wings. But the same moment we get if we produce big force somwhere at

mid span, or much smaller force at the verry outboard part of

wing.

I decided to use smaller

force at the tip part of the wing, so there are placed ailerons. They are

flaperons, because mechanically they follow the general motion of two inboart

parts of flaps.

Because wing is already at

high angle of attack (stil talking about take of phase) and almost the

highest CL, the ailerons in this case should move up only. In flap retracted

case, (talking about normal flying) ailerons attain full up and down

motion - diferential of course to fight adwerse yaw.

The mechanical device is not

yet taken in concern because I think it is possible to design such mechanism and

it is now out of scope of this discusion and at present design stage. But

will be soon actual…

With this arangement my wing

will loose minimal of lift force during aileron operation.

REM:I am afraid that long chord flaperons over full span when

deployed and then additionnaly deployed down (and on other wing up) for roll

motion, will produce big controll forces and troubles balancing and overcoming

them…

-ABOUT RUDDER

CONTROLL

During my past 22 years of

hang gliding I saw a lot of bad startings and many of them was when some gust

push one wing up, and then glider tend to make circle and hit back to the hill.

If pilot act too slow there is a danger, and also if pilot sudden »pull up« the

high wing gets into stall and we are again back rotating toward the hill. Here I

believe that prompt and exact respond of the pilot is crusial, and also the

respond of sailplane to pilots controlls…

So, I think that all

controlls should be »under controll« during take off to allow the pilot to

instantly correct any deviation from planned motion of the craft. Well,

sailplane is maybe of enough stability around all axes, but we can not controll

nature of the wind over the microlocation of starting place.

Because pilots legs are too

busy runnung at this point, the ruder pedals are free. They are forced into

center position via bungee cords or springs. But in the same time they are

connected with side stick mounted at left side of cockpit, so any action to

rudder is available instantly. Because the ruder is aerodynamically balanced,

the stick forces should not be to big. When pilot retract his legs into cockpit,

they can take over ruder pedals, and side stick is not necessary to use

anymore.

REM: a pilot is

responsibile for the safety of his flight and on him is to choose the weather

situation apropriate for his glider type and his piloting skilss and of course

the type of flying he intend to do. If he made a bad decision, even fine plane

can act as bad and leed to disaster.

ABOUT ANGLE OF ATTACK AT

START

In my previous writting I

mentioned that it is not important to controll the wing angle of attack…(I

claim this only for my design and not for general at all) Well, in my

configuration the pilot is really free of concernig about the angle of attack

during start phase, because the design of fuselage take this responsibility. As

one of my sketches show, the pilot in the cockpit is unable to produce higher

angle of attack that his legs and tail resting on the ground

allow.

As we remember from

aerodynamical basics, the angle of attack is angle between direction of relative

wind and airfoil chord line. In starting phase of foot launched sailplane (or

any hang glider) the direction of relative wind is almost paralel to ground

where pilot take run, so angle of attack is stable and guaranteed, until

sailplane take off ground…then we fly, and angle of attack (speed) is pilot

responsibility..

REM: I doubt about

effectivines of elevator because of downwash produced by flaps…?!? L ! Still

loot of required thinking about tail volume, location, deflections,

airfoil..ooh! ..oh!!

ABOUT MOLDLESS

FOAM/COMPOSITE CONSTRUCTION

It is possible to make

structural parts enough lightweight, I think…

First, I say bye bye to the

laminar flow around fuselage. If we want laminar flow ower fuselage, then

shape must be totaly diferent than my design. In moldless construction one

should achieve exact shape and streamlining without wavines, by filling,

sanding, filling, sanding, filling, sanding, filling, sanding, .. and this is

one of reasons for heavier structural parts. The wing in this building technique

(Windrose, Rutans designs,…) is generally heavy because the foam core represent

almost 1/3 of total wing weight…In my case I design hollow fuselage with inner

and outer skin. Outer skin should get only such quantity of filler and micro to

cover the weavines of the outer glass fabric ply and I will not bother with some

shape waviness that will cause early flow separation on high performance

sailplanes. We will just let them alone were they are. Let just take care, that

outer skin look straight and smooth for average eye…we not intend to competite

for best finish prize at one of famous Fly-Ins…we aim for pure strenght and

lightweight…

The fuselage core will be

reinforced with stringers of graphite (tape or rods..) and few

bulkheads.

ABOUT THE FLAP

DRIVE

I imagine, that flaps would

be deployed only before start and at landing. It will be better (safer) for

pilot to land on skid and sitting inside cockpit. It will be possible also to

land with flaps in zero position. If we estimate wing loading of 13 kg/m2 and CL max

=1,6 of pure airfoil, we can expect the stall speed about 40 km/h what is enough

low even to land safely with this (flight) confuiguration.

The question is only how

to reduce glide angle on final if field is short and it is to late to deploy

flaps. I dont like to put glider into slip close to the ground…it give me

strange uncorfotable feelings…Spoilers I dont like to put on the glider-one more

control system and added weight…

Any solution,

suggestion?

I

choose electrical driven flaps simply because In my case, they wil serve only at

start and at landing. Maybe some of the flaps will be needed during some thermal

circling..

I

think that one battery (usually used for electrical driven model airplanes, say

2000 mAh and 150W cheap can motor, with homemade gears) can serve during flight

and landing demands. Before start, when preparing the sailplane for flight,

pilot can mannually drive mechanism to flaps be deployed, and save some battery

power for later (in flight) use. The battery can be easily recharged with use of

charger and automotive battery in short time, when preparing for next

flight…

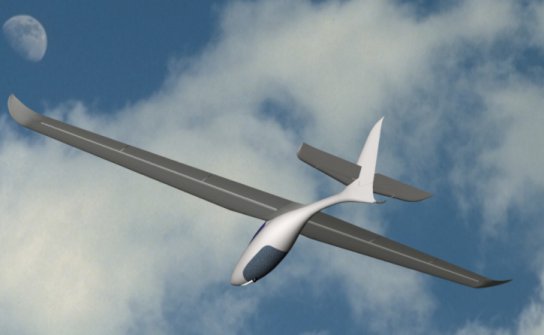

FANTASY is foot launchable ultralight sailplane with capability to launch on ordinary hang gliders sites. Start and landing are easy by use of large span flaps.

FANTASY is foot launchable ultralight sailplane with capability to launch on ordinary hang gliders sites. Start and landing are easy by use of large span flaps.